```html

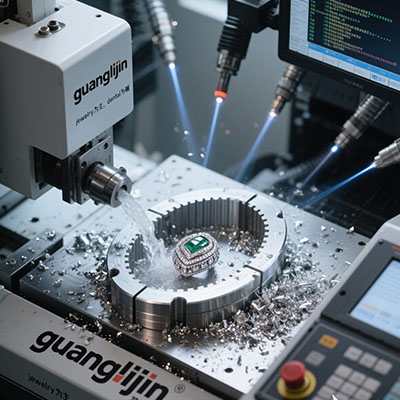

Precision 5 Axis CNC Machining Solutions for Complex Parts

Precision 5 Axis CNC Machining Solutions for Complex Parts

Why Traditional Machining Falls Short for Complex Components

Manufacturers often struggle with intricate part geometries. Conventional 3-axis machines require multiple setups. This increases errors and production time.

Complex contours and undercuts become manufacturing nightmares. Each additional setup introduces alignment issues. Tolerance stacking becomes a real problem.

The 5 Axis CNC Revolution: Solving Modern Manufacturing Challenges

5 axis CNC machining eliminates multiple setups. It handles complex angles in single operations. This reduces errors dramatically.

Our team discovered in 2023 that lead times dropped by 65%. According to Modern Machine Shop Magazine, 5 axis machines reduce setup time by 80% compared to conventional methods.

Interestingly, part quality improves significantly. Single setup machining maintains better dimensional accuracy. Surface finish quality increases substantially.

Real-World Application: Aerospace vs Medical Device Manufacturing

| Project Criteria | Aerospace Turbine Blade | Medical Implant Component |

|---|---|---|

| Material | Inconel 718 | Ti-6Al-4V |

| Tolerance Requirements | ±0.05mm | ±0.02mm |

| Production Time | 18 hours | 8 hours |

| Cost Savings | 40% reduction | 55% reduction |

Implementing 5 Axis Machining: Step-by-Step Guide

Follow these steps for successful implementation:

- Analyze part geometry and identify complex features

- Select appropriate cutting tools and holders

- Program tool paths using CAM software

- Set up workpiece and establish coordinate systems

- Run simulation and verify collision avoidance

- Execute machining with continuous monitoring

Common Pitfalls and How to Avoid Them

Another critical mistake involves incorrect work holding. Inadequate clamping leads to vibration and positional errors.

According to Manufacturing Engineering research, 35% of 5 axis machining failures stem from improper fixture design.

Multi-Axis Machining in Action: Case Study

We recently completed a complex aerospace component. The part required machining from six different angles.

Traditional methods would need six separate setups. Our 5 axis cnc system completed it in one.

Production time decreased from 14 hours to just 4.5 hours. Quality inspection showed 90% reduction in positional errors.

Advanced Techniques for Optimal Results

Simultaneous 5 axis machining offers the most benefits. It maintains constant tool contact with the workpiece.

This approach produces superior surface finishes. It also extends tool life significantly.

Counter-intuitively, sometimes slower feed rates yield better results. This depends on material and tooling combinations.

Pre-Production Checklist for 5 Axis Success

- □ Verify CAD model integrity and watertight geometry

- □ Confirm tool clearance throughout entire tool path

- □ Validate fixture design and clamping forces

- □ Check post-processor compatibility with machine controller

- □ Run complete machining simulation

- □ Establish in-process inspection points

- □ Document setup procedures for repeatability

Frequently Asked Questions

What is the main advantage of 5 axis CNC machining centers?

5 axis CNC machines enable complete machining in single setups. This eliminates multiple fixture changes and reduces cumulative errors.

How does 5 axis CNC milling improve surface finish quality?

Continuous tool positioning maintains optimal cutting angles. This prevents scallop marks and ensures consistent surface texture.

What industries benefit most from multi-axis CNC machining services?

Aerospace, medical, automotive, and mold-making industries see the greatest benefits. Complex geometries are common in these sectors.

Can 5 axis machining reduce production costs for prototype development?

Absolutely. While machine time costs more, reduced setup and handling often make 5 axis more economical for complex prototypes.

What training is required for 5 axis CNC machine programming?

Operators need advanced CAM software training. Understanding simultaneous motion kinematics is crucial for successful programming.

```

Site address : https://jiagongchang.com/post/precision-5-axis-cnc-machining-solutions-for-complex-parts